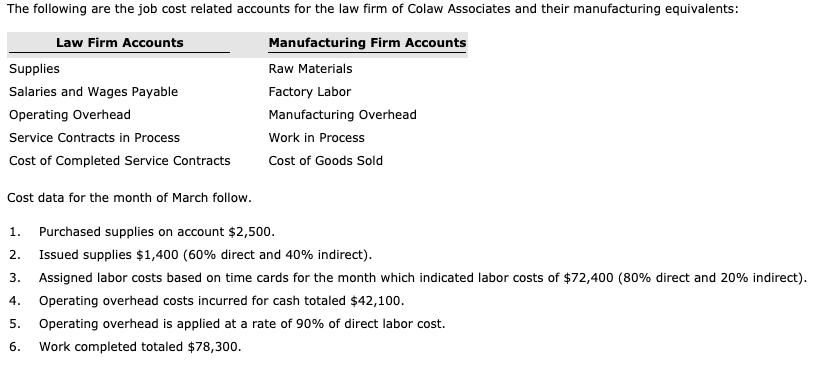

The job consumed $1,800 worth of materials. The job used 45 direct labor hours and 30 machine hours. K’s Premier Cabinets completes job #322 on July 7. The total cost of all the jobs completed over the course of the year is cost of goods sold. Total Job Cost = Direct Materials + Direct Labor + Applied OverheadĮvery time a job is completed, overhead is applied to the job. Applied overhead is added to direct materials and direct labor to calculate total job cost. For each direct labor hour worked, we will add $6.25 of overhead to the job.Īpplied overhead is overhead added to a job by taking the predetermined overhead rate multiplied by the actual activity. How do we apply this to our jobs? Based on the direct labor hours worked on the job. The rate from our example above is $6.25 per direct labor hour. $1,250,000 / 200,000 direct labor hours = $6.25 per direct labor hour (don’t forget to label your numbers) Applying the predetermined overhead rate to jobs The example states that estimated activity is 200,000 direct labor hours. Predetermined overhead rate is estimated overhead divided by estimated activity. Calculate the predetermined overhead rate assuming that the company uses direct labor hours to allocate overhead to jobs. The company believes that employees will work 200,000 hours and that 150,000 machine hours will be used during 2015. The company estimates that it will have $1,250,000 in overhead costs in 2015. K’s Premier Cabinets uses job costing to calculate the cost of jobs as they are completed. Most companies use direct labor hours or machine hours to allocate overhead costs. The company can choose any activity it believes will most accurately apply the overhead costs. Predetermined overhead rate = Estimated Overhead / Estimated Activity We call this rate the predetermined overhead rate. We can use those estimates to calculated a rate that we can apply to our jobs. These budgets include estimated overhead and estimated activity. Most businesses complete budgets prior to the beginning of each year. If we don’t know the actual costs, how can we allocate overhead fairly to all of our jobs? We are going to use estimates. Is it ethical to allocate that $100,000 only to the jobs that are completed in March or April? No, those costs should be allocated to all jobs completed throughout the year, not just those unlucky customers who happened to place in order with our company in March or April. For example, what if we get the annual renewal for our insurance policies in March. We could use overhead costs for the current or previous month and apply those costs to the job, but what if our overhead costs vary greatly from month to month. We can’t wait that long if we want to determine if we are making profit on our jobs.

If we waited until we had all the overhead spending calculated for the year, it would be January of 2017 before we know if jobs completed in 2016 were profitable or not. We could wait until the end of the year, when we know actual numbers but that does not help us determine if our jobs are profitable when they are completed. Since overhead is such a large part of the cost of operating a business, we cannot ignore it. Without allocating overhead to jobs, we do not have an accurate idea of the cost of the job.

Overhead can cause problems for organizations that use job costing. Employees track which jobs they are working on throughout the week so that direct labor costs can be added to the job cost sheets. Companies use job cost sheets to record the cost of materials used on the job.ĭirect labor is easy to calculate as we know how much each of the employees earns per hour and how many hours the employees worked on the job.

It is easy to calculate the total cost of direct materials based on the materials used in the job. Therefore, each job has a unique total cost.ĭirect costs are easy to assign to jobs. All jobs require different amounts of material, labor, and overhead. Each cabinet is custom built based on measurements made inside the customer’s home. Imagine a cabinet maker who makes custom cabinets for homes. Job costing is a cost allocation method used by companies that make custom products. One object that is used frequently by job costing. We have previously discussed cost objects and assigning costs to cost objects.

0 kommentar(er)

0 kommentar(er)